Electricity from Wind

About wind power.

Wind power is one of the oldest forms of energy used by man. Windmills have been used for centuries to make mechanical work easier. In the 19th century, the first attempts were made to convert the mechanical energy into electrical energy. The advance of wind power began with the progress in technology, the increasing demand for energy and growing awareness for the environment.

All about energy conversion

Solar radiation heats the earth’s surface and the air masses above it to different degrees depending on the geographic region. Thus, the radiation at the equator is stronger than at the poles. Water masses heat up more slowly than land masses but also release their heat more slowly, as a result land masses warm up faster during the day but also cool down faster again at night compared to water masses. The rising air in very hot regions creates areas of low pressure while high pressure areas form in cooler regions. To compensate for these differing pressure areas, air flows from high to low pressure areas creating wind.

Wind, therefore, is nothing but moving air.

In the generation of electricity by wind power, the wind movement is converted into rotational energy by means of the rotor blades which transfer the wind’s energy into a rotary motion. The rotor transmits this rotational energy to a generator which produces electric current from it. The amount of electricity produced depends essentially on the diameter of the rotor, the generator’s output, the hub height, and the wind strength.

In the case of a wind turbine, therefore, the kinetic energy is converted into electrical energy.

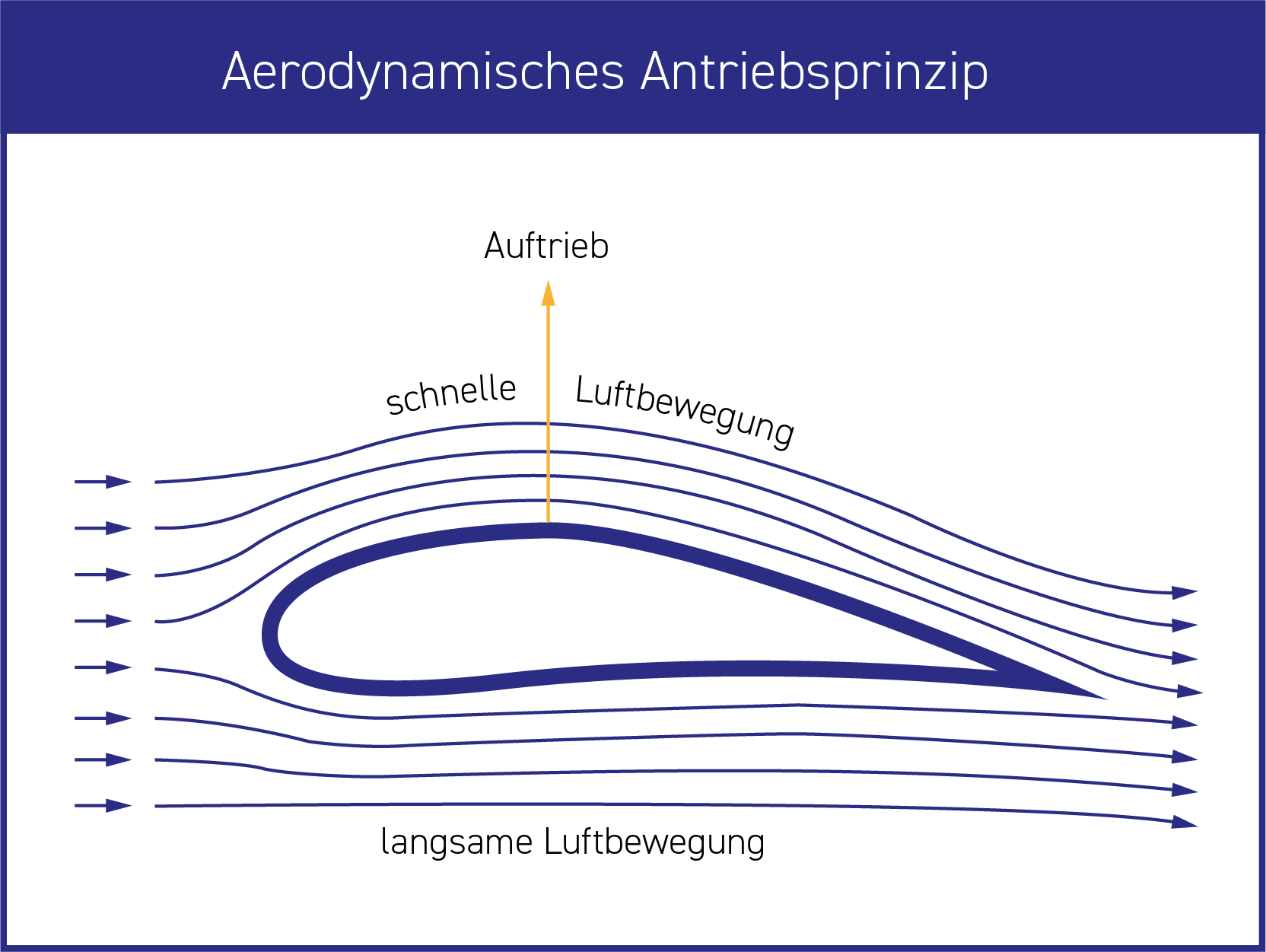

When converting kinetic energy into rotational energy, all common types of turbine use the principle of aerodynamic lift. If an air flow has to flow around a convex-shaped rotor, a positive pressure forms under the wing, while a negative pressure prevails above the wing. These differences in pressure create an upward force which sets the rotor blades of the wind turbine in motion.Which wind speeds are optimum?

Wind power becomes usable for electricity generation above a wind speed of 3 to 4 m/s, depending on the turbine type. The rotor blades begin to turn above this wind speed. The output increases with the cube of the wind speed. If the wind speed doubles, the output increases eightfold. The generators achieve the rated power, that is the maximum energy yield, at 12 to 15 m/s, which they then keep constant even at higher wind speeds. The active blade pitch at different wind speeds optimises the energy yield of the pitch-controlled Enercon systems. This state-of-the-art, efficient control technology in which the power is adjusted to the wind speed by rotating the rotor blades (controlling the angle of incidence), guarantees operation of the wind turbines even in strong winds and storms (above 25 m/s). Only above a wind speed of 30 m/s (hurricane strength) are the Enercon wind turbines switched off automatically due to the wind being too strong.

DunoAir optimises your energy yield

When converting energy into the various energy forms, some of the energy utilised is released into the environment unused. Thus, purely physically, a wind turbine can only use 59% of the kinetic energy contained in the wind and convert it into mechanical energy. However, due to aerodynamic, mechanical and electrical losses, this theoretical maximum calculated by Albert Betz is not achieved in practice. Thus, aerodynamic losses arise due to friction and turbulence on the rotor blade and the swirl effect in the rotor’s wake. Mechanical losses are caused by friction in the bearing and the gearbox as well as in the generator itself. Heat generated by electrical resistances in the converter and cables cause electrical losses. Due to these conversion losses, our state-of-the-art Enercon wind turbines now achieve a yield of between 40 and 50%.

Components of a wind turbine

Cutting-edge wind turbines for grid-connected power generation are high-tech units consisting essentially of 50 to 150 m tall tower structures, the nacelle with mechanical equipment and the rotor with horizontal axis and three rotor blades..

Foundation

The foundation is the link between the tower and the subsoil and bears all the static and dynamic loads arising from the wind turbine. The foundations of our Enercon wind turbines are circular and consist of a steel mesh that is lined with concrete. The circular shape has the advantage that the effect of the forces is the same for all wind directions and the volume of concrete and steel to be installed is demonstrably reduced. Filling the foundation with the excavated soil from the excavation pit additionally makes it possible to ensure stability even with a smaller diameter.

Tower

The tower is the largest and heaviest part of the wind turbine. Enercon produces towers which are between 50 and 150 m tall and weigh several hundred tonnes. Among other things, the height of the tower is crucial to the yield situation at a location. The higher the tower, the lower the loads due to turbulence and the higher the wind speeds. We are therefore moving towards ever-increasing hub heights with which higher yields can be achieved.

Tubular concrete structures which are transported to the site in segments and assembled in situ are the preferred tower design for our Enercon wind turbines.

The green stripes at the foot of the mast are another special feature of the Enercon towers. The various shades of green are used to better integrate the towers into the natural landscape.

Rotor

The rotor “captures” the wind’s energy and passes it on to the drivetrain. The rotor hub connects the rotor blades to the rest of the system and transmits the power to the rotor shaft. In our wind turbines, braking of the turbine is also controlled via the rotor blades. The blade angle adjustment (pitch control) makes it possible to limit the power output of the turbines at high wind speeds. The position of each individual rotor blade in relation to the wind can be controlled using so-called pitch motors, thus actively controlling the aerodynamics. This has become necessary because the rotor blades used nowadays with lengths of 35 to over 60 m develop very high forces that are no longer manageable with mechanical brakes.

The modified blade geometry, which also uses the inner part of the rotor disc surface and thus increases its efficiency, is particularly important in the Enercon rotor blade concept. The blade tips are also optimised with regard to noise emission and energy yield.

Nacelle

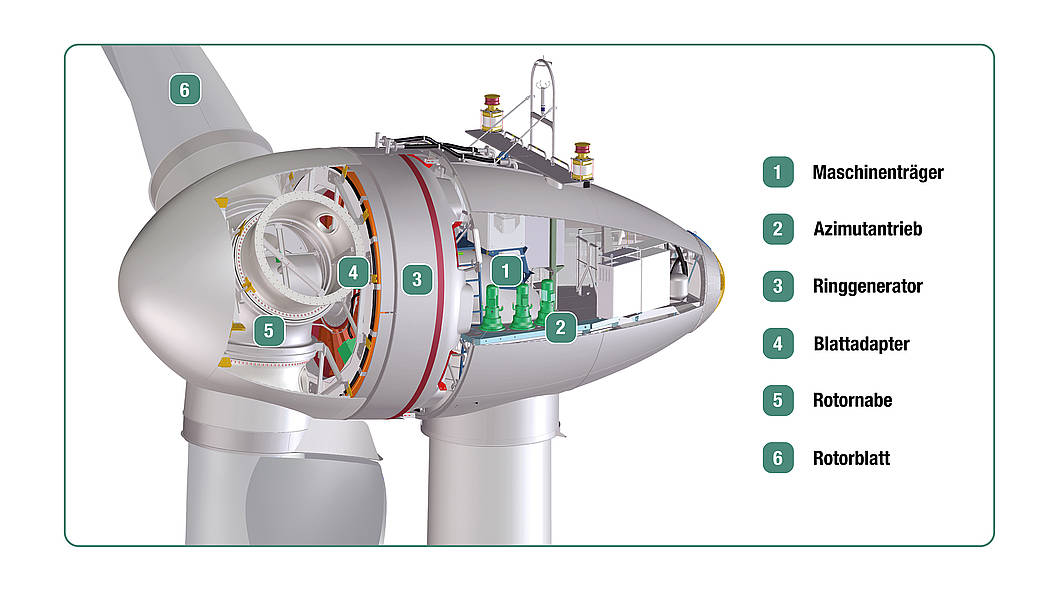

sectional drawig: Enercon nacelle The nacelle is located on the top of the tower and houses the whole machine set of a wind turbine. The central component is the drivetrain which, in the case of our Enercon turbines, consists of rotor hub, rotor shaft with bearing and generator. Enercon wind turbines have the characteristic egg shape to accommodate the large annular generator in the nacelle. The nacelle is rotatably mounted on the tower due to the necessary yaw control and can be rotated by so-called azimuth motors. They are used to rotate the wind turbine optimally into the prevailing wind direction. From a purely visual point of view, the wind turbines planned by DunoAir can be identified by the blue company logo on the nacelle.

Gearless wind turbine concept

Gearless wind turbine concept DunoAir plans to use only the gearless concept of the Enercon wind turbines in its wind farms. In gearless wind turbines, the rotor directly drives a large-diameter special synchronous generator (an annular generator). This annular generator is directly connected to the hub of the wind turbine and turns slowly at a rotor speed of 6 to 20 revolutions per minute. The output voltage and frequency of this multi-pole synchronous generator vary with the speed and are converted for transfer to the grid via an intermediate DC circuit with inverter.

In contrast to gear-driven wind turbines, the gearless wind turbines which we use in our plans have fewer moving parts and hardly any mechanics, thus guaranteeing less material wear and longer lifetimes. Maintenance, oil changes and repairs to the gearbox also become superfluous. The only disadvantage of the gearless wind turbine concept is the size and weight of the annular generator which is considerably larger and heavier than a traditional synchronous generator.

Principle of DunoAir Windparks

The largest wind turbines we use in our planning now achieve an output of 3 to 7.5 MW and have a rotor diameter of 80 to 141 metres. In addition to continuous output monitoring and control, the wind turbines have early fault detection and systems for lightning protection and are usually located in wind farms. While individual wind turbines were often operated in the past, most wind turbines are now combined in wind farms so that synergy effects can be generated with regard to grid feed-in and maintenance work. The landscape is also less affected by the large state-of-the-art wind turbines in wind farms as individual locations are better utilized so that other areas can remain free. In addition, the areas around the wind turbine continue to be available to agriculture or nature.

Potential locations for wind power

In addition to the coastal areas, good wind regions in Germany are increasingly inland locations. In view of the steadily rising mast heights, the exposed positions of the low mountain ranges are becoming very attractive for the erection of wind turbines.

When designating wind priority areas in the regional plans of the German states, the minimum distances to residential areas and traffic routes, to nature reserves and biotope areas, to bodies of water as well as to military bases and airports serve as a basis for decision-making. When priority areas are found and designated, more refined site planning must take into account nature conservation interests, particularly species protection. An environmental impact study is conducted to assess interventions in the natural surroundings and landscape and to define any necessary compensation measures. In addition, the local wind conditions of the site selected are analysed in detail and the noise and shadow emissions are determined. The exact layout of the wind farm is ultimately determined based on the results of the preceding studies.

Feed-In to grid

The rotating movements are converted in the generator into electrical current with a voltage of 400 volts. The amount of electricity generated depends essentially on the diameter of the rotor, the hub height, and the wind strength.

To feed electrical energy into a grid, this electricity must be adapted to the line frequency, phase difference and voltage.

Like the majority of today’s wind turbines, our planned Enercon turbines are operated at a variable rotor speed. With the aid of a converter, the generator’s variable frequency is then adapted or synchronised to the desired line frequency - in Europe this is 50 Hz.

The electricity generated is transferred to the nearest substation via a transformer which raises the voltage to 20 kV depending on the local line voltage. From here the electricity is fed into the power grid from which the end consumer obtains its electricity.

The power grid as a transmission medium for electrical energy between wind turbine and end consumer is divided into a transmission and a distribution grid level. Wind turbines are mainly connected to the distribution grid system. Grid connection here is usually carried out at the medium and high voltage level.

Repowering for optimum energy efficiency

Repowering is now a key tool for increasing wind power generation on land. Older, smaller wind turbines with low yields, such as were built in the early days of the wind industry, are replaced by state-of-the-art and more powerful turbines. This results in several advantages:

- Increase in energy efficiency with decreasing number of wind turbines

- Increase in municipal revenues due to business tax

- Restoring the natural character of the landscape by reducing the number of wind turbines and eliminating individual wind turbines

- Improvement of grid integration

Wind turbines have a long service life of 25 to 30 years. Due to the great advances in technology, however, it makes sense to replace older wind turbines before the end of their service life to take advantage of the benefits of progress, relieve the strain on nature and landscape, and achieve higher yields. Repowering also provides the opportunity to correct design errors from the pioneering years thus leading to greater acceptance within the population.

Maximum energy output

Depending on the type, a wind turbine starts to produce electricity from a wind speed of approximately 3 metres per second (m/s). The maximum energy output is achieved at a wind speed of 12 to 13 m/s. When the wind speed exceeds 28 m/s (hurricane force), the turbines are automatically switched off. The turbines only switch on again when the wind speed has subsided to an acceptable value.